The magnetic drive in the Apexs M series offers several benefits. It provides superior precision and increased speed compared to traditional mechanical systems. Furthermore, it experiences less wear and tear, requires less maintenance, operates quietly, and is more energy efficient.

Apex M Series - Next Generation Cutting System

The Apex M Series takes our Flatbed Cutting platforms into the Next Generation. New Magnetic Drive Technology replaces traditional traverse systems using synchronous belts or rack & pinion. This allows for greater precision, speed and overall performance. The “Zero Contact” transmission system achieves optimized acceleration factors while reducing potentially costly mechanical wear & tear. Another key feature of the Apex M Series is the robust frame that is constructed from High-Quality Carbon Structural Steel.

Flatbed Cutting Redefined

Magnetic drive for “Zero Contact” transmission system

2000mm/s maximum traverse speed

2g linear acceleration

Multiple Table Size Solutions to match application

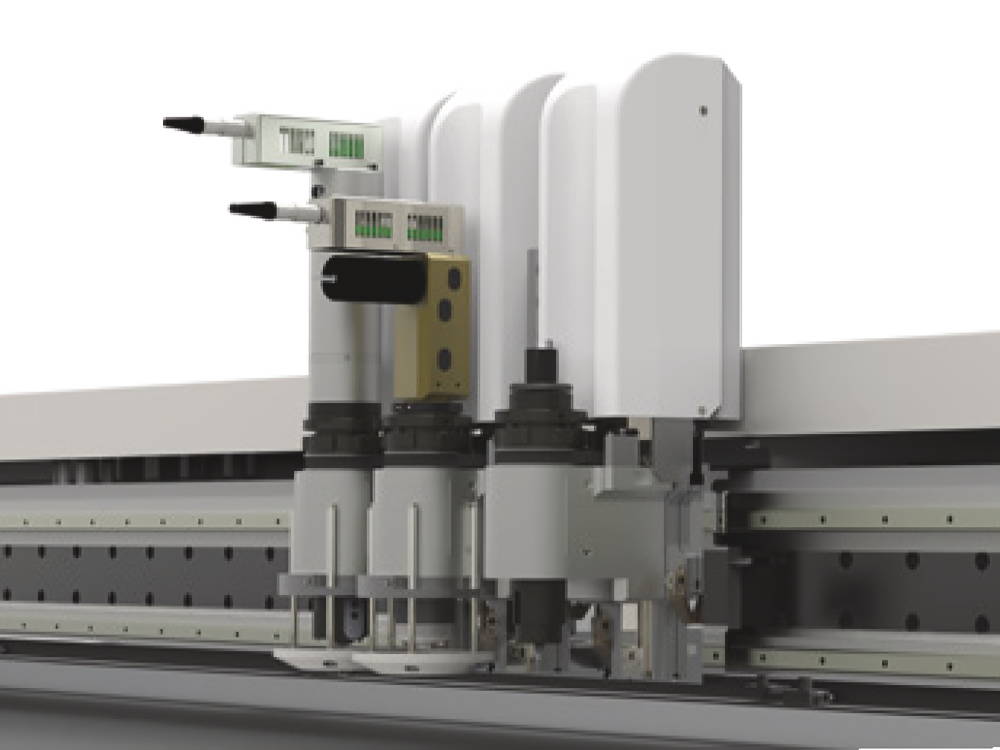

True 3 tool interchangeable positions available for many tool combinations

Independent Servo Controlled Tool Head Modules - Tool Head Modules controlled independently

Optical Auto Tool height calibration

Vision Registration System & Camera

Automatic Router Bit Tool Changing options available for APEX M Series models

Variably controlled Vacuum Zones table controlled by our software to adjust the vacuum power output & active zones

Compatible with auto sheet feeding system for increased production

Standard integrated Roll Feed attachment & Clamping Bar

Noise level under 65db

Modular framework platform

Service and Support by our expert in house engineers and specialists Parts & Supplies in stock at CUTWORX USA, Irving Texas

Magnetic Drive Benefits

Increased Precision: Magnetic drives offer superior precision compared to traditional mechanical systems, providing the ability to cut intricate and complicated designs with high accuracy.

Enhanced Speed: Magnetic drives allow for higher traverse speeds, improving the overall productivity of the cutting process.

Reduced Wear and Tear: Magnetic drives experience less wear and tear from mechanical moving parts, extending the lifespan of the equipment.

Lower Maintenance: With fewer moving parts and no physical contact, magnetic drives require less maintenance, saving time and costs.

Noise Reduction: Magnetic drives operate quietly, providing a more comfortable working environment.

Questions About the Apex M?

Experience the M Series Difference

- Precision Cutting: Apex M cutters provide extraordinary precision, ensuring exact cuts every time, saving on material waste and reducing errors

- High-Speed Operation: Flatbed Cutters operate at high speeds without compromising on accuracy to reduce production time

- Versatility: Apex cutters can handle a wide range of materials, from paper and cardstock to leather and certain types of plastic, making them suitable for various applications

- Increased Productivity: Automated features increase productivity and efficiency by reducing manual labor

- Triple Interchangeable Tool Heads: The ability to manage multiple tool positions on a single sheet allows for adaptable cutting processes, catering to a variety of production needs

- Seamless Integration: Apex Series Cutters can be easily integrated into existing production lines, making them a valuable addition to any operation

- User-Friendly: With an intuitive control system, these cutters are easy to operate

- Durability: Apex Finishing Systems are designed to withstand high-volume operations, ensuring reliable, long-term performance

- Cost-Effective: By combining multiple functions into one machine and reducing manual labor, these cutters are a cost-effective solution for businesses of all sizes

- Safety Measures: Safety is our highest priority with features built into the design to ensure safety during operation

Applications

Signage

Packaging Prototyping

Labels

Banners

POP Displays

Sticker and Decal Production

Textile Cutting

Paper Crafts

Gasket Cutting

Acoustical panels

Solutions for Graphics Markets

- Commercial print facilities

- Trade Only Printers

- DOT, City/Municipality

- Sign Shops

- Packaging/Prototype

- In-House Production Graphics

- PSP's Franchises

- Soft Signage & Textile production companies

- Any Solvent/UV printer owners

Solutions for Speciality Markets

- Corrugated Packaging

- Furniture/Upholstery Industry

- Display Production

- Gasket Manufacturing

- Signage Production

- Specialty Textile

- Labels & Decals Production

- Technical textile & Acoustic Panel Production

- Sample Making/Prototyping

Efficient Cutting Heads

The max cutting speed is 2m/s (6 to 8 times faster than manual cutting) which considerably increases the productivity.

Complete Cutting Tools

APEX M cutting systems have a complete set of cutting tools for Acrylic, Corrugated board, Fabric/Textiles, Foam, KT Board, Paper PVC, Vinyl and more. The cutting tools support through-cutting, half-cutting, V-cutting, engraving, creasing, marking, etc.

Automatic Positioning System

The high precision CCD registration camera can account for multiple types of printer distortion.

Router

1.8kw (2.4hp) featuring industry standard 6mm collet with pneumatic chuck. This module is compatible with automatic router bit tool changers.

Auto Tool height Calibration

The automatic knife initialization tool uses an infrared sensor to control cutting depth accuracy and streamline the tool measuring process.

Tool Changer

The Apex M Automatic Tool Changer is available for the 1.8kw Spindle. It can hold up to 7 different routing bits.

Vacuum System

The 15hp vacuum zones and power output are controlled by the interface for different material hold down requirements.

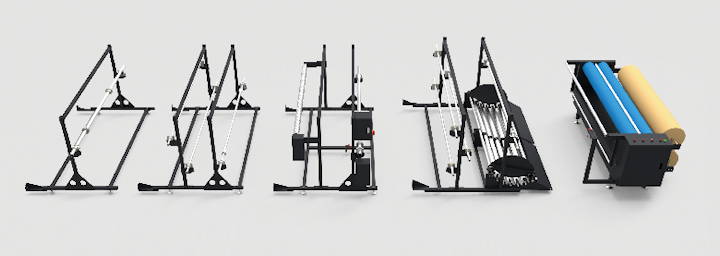

Continuous Cutting System

The automated conveyor system streamlines the feeding, cutting and collection workflow. Its continuous cutting function can process oversize pieces therefore saving labor cost and increasing productivity.

Safety Freaures

Each machine is equipped with mechanical safety bumpers and infrared barriers.

Material Unwinding Devices

Various unloading systems are available to handle rolls of every size.

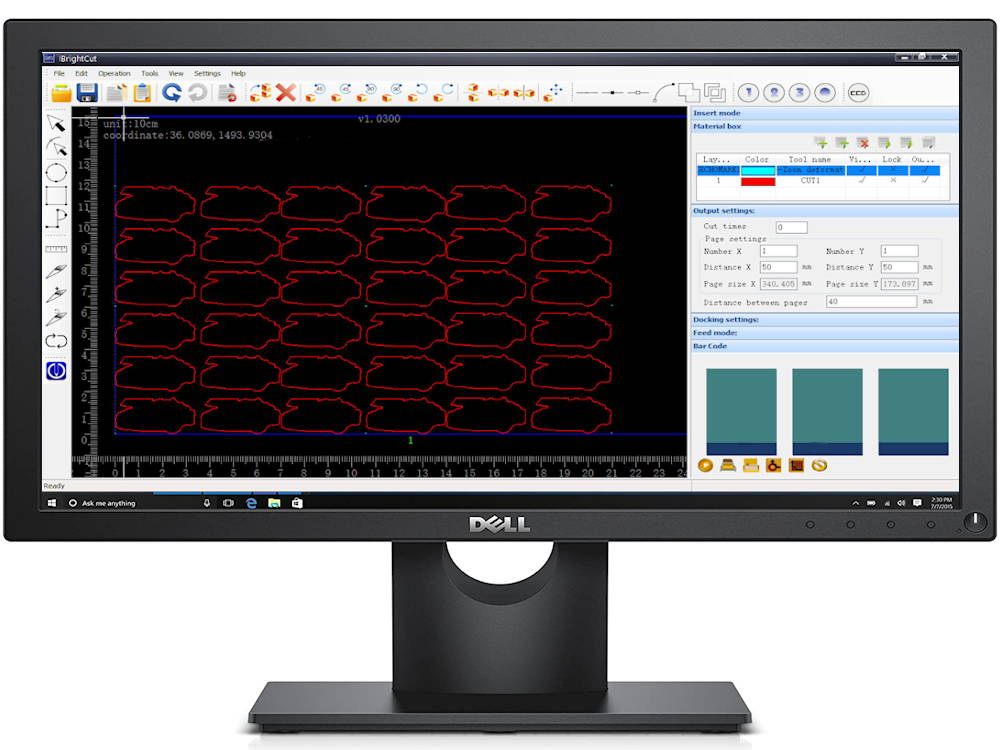

Integrated Controls

The CUTWORX software suite is a user friendly and intuitive control system. This straightforward Auto Processing Workflow is designed to handle jobs in the most productive way.

Frequently Asked Questions

What are the benefits of a magnetic drive?

How does the Apex M enhance productivity?

With its high precision and speed, the Apex M significantly reduces the time taken for cutting tasks, thereby increasing overall productivity.

Is the Apex M suitable for large scale production?

The Apex M Digital Flatbed Cutter is designed to handle both small and large scale production needs, making it a versatile tool for various industries.

How does the Apex M maintain its cutting precision over time?

The Apex M is built with a precision aluminum table to ensure it maintains its precision over time. Regular maintenance and cleaning also help keep the machine in optimal condition.

How does the Apex M contribute to increased productivity?

With its high precision and speed, the Apex M can significantly reduce the time taken for cutting tasks, thereby increasing overall productivity.

What safety measures are in place for the Apex M cutter?

The Apex Plus includes safety features such as emergency stop buttons and safety sensors that stop the machine if an obstacle is detected. Detailed maintenance instructions are provided with the machine., and additional support is available by CutworxUSA if needed.

Trusted by the Industry

TOM C

"“The Apex Pro has been a complete game changer for Sticker Bros. From the high speed accurate cutting to the easy to use software, the Apex Pro does anything we could imagine with ease."

Apex M Digital Flatbed Cutter Series

How Can We Help?

CUTWORX USA

Excellence Delivered, Trust Earned!

We are Your Reliable Partner for

Complete Finishing Solutions

First Class Service and Support, Tailored Just for You

One Year Warranty

Personalized Training for Your Success

Free Phone Support

Delivery and Installation

Experience the Future of

Print Finishing.

Schedule Your Apex M

Cutting System Demo Today!

Questions About the Apex M?

Send us a message or call us at: 469-758-2288