The Eclipse can handle a wide range of materials including paper, cardboard, fabric, and plastic among others.

Revolutionizing Precision Digital Die Cutting

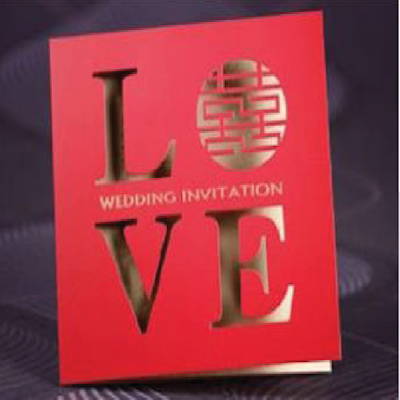

The Eclipse S Series Digital Die Cutters are versatile sheet-fed flatbed cutting systems requiring no dies for continuous feed and cut production for the printing, packaging and sign industries. The Eclipse S Series is cost-effective solution for sample making and short-run production of adhesive sheets, business cards, specially shaped cards, invitations, labels small packaging, tags and more.

Discover The Game-Changing Benefits

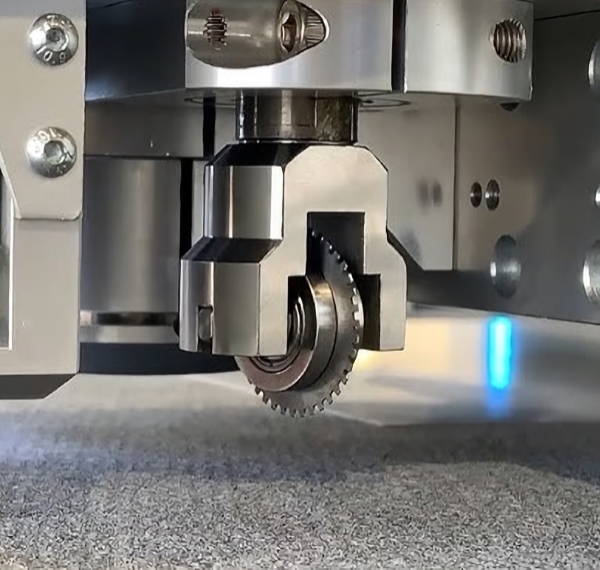

No Cutting Dies: The Eclipse S Series is equipped with 4 integrated tool positions, all of which can be utilized on a single sheet. This allows for a flexible range of material processing using the Electric Oscillating Tool, Drag Knife, Kiss-Cut Tool, or Creasing Wheel. For even greater flexibility in your operations, options for Perforation and V-Cut Tools are also available.

Multiple Tool Combinations: Meet all your creative processing demands. Cut labels of any shape or cut and crease cardboard for packaging on single sheets without the need of switching tools manually.

High Precision Vision Registration System (CCD): Equipped with a high-definition CCD camera, the Eclipse S Series can automatically and accurately carry out contour cutting on a range of printed materials or scan QR codes for automated variable data workflow production needs.

Software: CUTWORX Software Suite features Design Manager and Cut Software designed for file preparation of PDF, PLT, DXF, HP/GL and is compatible with Kasemake, Artios, CAD, Adobe Illustrator, Box Magician and much more. The Eclipse can work with most RIP programs for quick workflow management such as Onyx, Caldera, or Fiery.

QR Codes: Optimize workflow production by utilizing the optional QR code module for automated feed and cut production for variable cutting data. Reduce downtime by scanning a QR code to import cutting data automatically and begin processing, eliminating the need for manual job switching.

Automatic Sheet Loading System: The Eclipse S Series is designed for streamlined production with an automatic sheet feeding system and conveyor. Eliminating the need for a dedicated operator, the Eclipse can continuously feed and cut utilizing the CCD Camera for precise registration mark scanning.

Roll Holder: Increase operational efficiency and production with an all-in-one solution. Integrate the Eclipse S Series with the optional roll feed attachment for roll to sheet processing for labels, stickers, decals and DTF material processing.

Support: CutworxUSA is commitment to providing top-tier customer support to maximize your machine's capabilities.

Questions About the Eclipse?

Experience the Eclipse Difference

- Precision Cutting: Eclipse cutters provide extraordinary precision, ensuring exact cuts every time, saving on material waste and reducing errors

- Versatility: Eclipse cutters can handle a wide range of materials making them suitable for various applications

- Increased Productivity: With automated features these cutters significantly increase productivity and efficiency by reducing manual labor

- Multi-Tool Capacity: The ability to manage multiple tool positions on a single sheet allows for an adaptable cutting process, catering to a variety of production needs

- High-Speed Operation: Achieve increased productivity without compromising on accuracy

- User-Friendly: With an intuitive control system, these cutters are easy to operate, even for beginners, reducing the learning curve

- Durability: Eclipse cutters are designed to withstand high-volume operations, ensuring reliable, long-term performance

- Seamless Integration: Eclipse cutters can be easily integrated into existing production lines, making them a valuable addition to any operation

- Safety Measures: With safety features in mind, these cutters prioritize operator safety during operation

- Cost-Effective: By combining multiple functions into one machine and reducing manual labor, these cutters are a cost-effective solution for businesses of all sizes

Short Run Digital Die Cutting

Package Prototypes

Custom Contour Decal

Cards

Solutions for

- Digital, Commercial, In Plant Printers

- Packaging

- Prototyping

- DTF (direct to film) Printers

- Custom short-run applications

Suitable Materials

ABS Board

Card Stock

Corrugated Plastic

Corrugated Board

Foam Board

Grey Board

- Magnetic Sticker

KT Board

Plastic Sheet

PP Paper

Reflective Material

Adhesive Vinyl

Applications

Business Cards: Cuts uniquely designed business cards

Greeting Cards: Ideal for custom-shaped cards.

Crafts and Arts: Cuts intricate designs for art projects

Custom Contour Cutting: Cuts any shape or pattern

Envelopes: Cuts custom-sized envelopes

Invitations and Stationery: Creates intricate designs

Label Production: Cuts various shapes and sizes of labels

Prototyping: Creates prototypes rapidly and accurately

Packaging: Makes custom packaging

Pocket Folders: Cuts precise folders.

POP Signage: Makes signs from various materials

Tags: Produces high-quality, custom tags

Vinyl Decals: Cuts precise vinyl decals

Knife Cutting Tools

2 plotter Knife Positions for pressure sensitive thru-cut and kiss-cut

Oscillating Cutting Tool

The integrated EOT cutting tool can handle a wide range of materials, including foamboards.

Perforation Wheel

The perforation wheel creates clean Perfs and Space lines, making it easy for tear off applications.

V-Cut

The V-Cut tool is used to cut at specific angles and depths for beveled edges and other unique projects.

Automatic Feeding System

Fully automatic feeding and conveyor system for continuous cutting of materials for a more efficient workflow and production.

QR Codes

Use integrated QR code functionality for quick and and easy job switching without needing to manually reconfigure the cutter each time. Requires optional software module.

Software

The Eclipse Software Suite features a Design Manager and Cut Software, specifically designed for file preparation in various formats such as PDF, PLT, DXF, and HP/GL.

Pinnacle Product Award

Frequently Asked Questions

What type of materials can the Eclipse handle?

What tools are integrated into the Eclipse S Series?

The Eclipse is equipped with four integrated tool positions including a Universal Cutting Tool, Drag Knife, Kiss-Cut Tool, and Creasing Wheel. Options for Perforation and V-Cut Tools are also available.

Does the Eclipse require manual loading?

The Eclipse features an automatic feeding system for continuous feed and cut production.

Does the Eclipse need to be purchased with the roll feed attachment?

No, the roll feed attachment can be added anytime for continuous roll to sheet processing of stickers, labels, decals and DTF materials.

Does the Eclipse require cutting dies?

No, the Eclipse software follows vector dieline paths created in Adobe Illustrator or comparable design programs.

What about support and service?

CutworxUSA technical team is ready to assist your needs for needs for service and support. Utilize our call center or email for a quick response.

Eclipse Series Digital Die Cutter

How Can We Help?

CUTWORX USA

Excellence Delivered, Trust Earned!

We are Your Reliable Partner for

Complete Finishing Solutions

First Class Service and Support, Tailored Just for You

One Year Warranty

Personalized Training for Your Success

Free Phone Support

Delivery and Installation

Experience the Future of

Print Finishing.

Schedule Your Eclispe

Cutting System Demo Today!

Questions About the Eclipse?

Send us a message or call us at: 469-758-2288