The Neolt XY Cutter is versatile and can cut a wide range of materials, including DTF, UV DTF, flock, glitter vinyl, heat transfer vinyl, reflective and vinyl.

Neolt is Revolutionizing XY DTF Digital Finishing

The revolutionary Neolt XY DTF Cutter Series is a professional game-changing solution for cutting Direct to Film (DTF) and Heat Transfer Vinyl (HTV) materials. This professional-grade machine is designed to cater to craft enthusiasts, PSPs, and Promotional Products businesses, offering a new standard for cutting Direct to Film (DTF) and Heat Transfer Vinyl (HTV) materials.

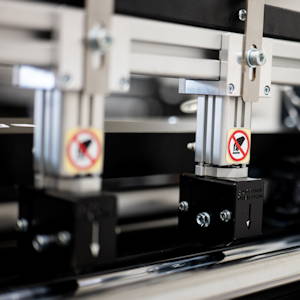

The Neolt XY Cutter, is a masterpiece of engineering and functionality designed to boost productivity for workflows involving 30” wide film/flexible media material. It offers the ability to slit or trim DTF or HTV materials along two dimensions, providing unparalleled precision and flexibility. Its robust internal compressor powers both the pressure roller for material advancement and the pneumatic vertical blade, making it a precise tool for processing DTF and HTV prints or designs.

Designed with user-friendliness in mind, the Neolt XY Cutter caters to both novices and professionals. Its intuitive touchscreen interface simplifies operation and allows precise control over the cutting process. It offers two main programs for optimizing production: an automatic mode for setting the size and quantity of copies, and a mark reading mode for automated cutting by mark detection. Integrated video tutorials and self-help videos offer guidance at every step.

The cutter's main features include a self-sharpening horizontal cutting wheel, adjustable pressure on the vertical slitter, mechanical skew alignment, waste collection basket, finished piece collection tray and separators, support stand, inline dancer arm for supported printers, and an intuitive control interface.

Discover The Game-Changing Benefits

Efficiency - XY cutter automates the trimming process, significantly reducing manual labor and increasing productivity.

Precision - High speed cutting precision ensures professional-quality cuts and less waste from errors.

Versatility - Can handle a wide range of materials, including paper, vinyl, laminates, and more.

Ease of Use - Intuitive easy to use touch screen interface reduced the learning curve and errors.

Speed - Designed and built for high speed production to increase efficiency and volume of output.

Durability - Built to ensuring it can withstand long-term, high-volume operations.

Cost Savings - By automating the cutting process, reducing waste, and speeding up production to save you money and time.

Support CUTWORX USA is commitment to providing top-tier customer support to maximize your machine's capabilities.

Questions About the Neolt?

Experience Cutting and Finishing Like Never Before

- High performace: Combined horizontal and vertical cutting for the fastest finish for your printed and unprinted rolls

Accurate cutting: Trimmed images perfectly square every time and zero mistakes thanks to the reading accuracy of the sensor of 0.05 mm.

Easy to operate: Intuitive touch screen control panel for maximum versatility.

Two operating modes:

1. Automatic: Programmed size and number of copies

2. Mark mode: 2 mark lines for automatic cuttingRotary crush cutters: The lengthwise rotary crush cutters are safe for the operator, last for 100's of thousands of cuts with low costs of maintenance. No need of special cleaning after cutting adhesive media as they create a “dry,” non-sticky edge

Mechanical movement: You can modify the angle inclination of the roll media.

Applications

DTF

UV DTF

Flock

Heat Transfer Vinyl (HTV)

Glitter Vinyl

Vinyl

Reflective

Expertly Designed

Easy to use touch screen control panel

Advanced cutting mark reader for perfect cuts

Optical sensor for vertical alignment

Fine positioning of the cutting blades

Rotary crush cutter are safe for the operator and last for 100's of thousands of cuts

Pressure adjustment according to the types of material

Ready to use, air compressor is bulit in

Optional collection tray

Touch screen control panel

Adjustable pressure for pinch roller

and vertical blade

Pneumatic vertical blade

Frequently Asked Questions

What materials can the Neolt XY DTF Cutter cut?

How precise is the Neolt XY DTF Cutter?

The Neolt XY DTF Cutter is designed for precision cutting, offering accuracy within a fraction of a millimeter for superior quality finishes.

How fast can the Neolt XY DTF Cutter operate?

The speed of the Neolt XY Cuter can vary depending on the material and complexity of the cut, but it is designed to offer a high-speed cutting solution while maintaining precision.

How easy is the Neolt XY DTF Cutter to use?

The Neolt XY DTF Cutter is designed with user-friendliness in mind, featuring an intuitive touch screen control panel for easy operation.

What is the maintenance requirement for the Neolt XY Cutter??

Regular maintenance involves cleaning and making sure the cutter is dust-free. Detailed maintenance instructions will be provided in the user manual.

How Can We Help?

CUTWORX USA

Excellence Delivered, Trust Earned!

We are Your Reliable Partner for

Complete Finishing Solutions

First Class Service and Support, Tailored Just for You

One Year Warranty

Personalized Training for Your Success

Free Phone Support

Delivery and Installation

Experience the Future of

DTF Print Finishing.

Schedule Your Neolt XY Cutter

Demo Today!

Questions About the Neolt?

Send us a message or call us at: 469-758-2288